Technologies

Technologies

Bottling Water Projects

Innovation is our forte and we strive to design and develop Bottling Plants. Advanced technologies are widely employed by the professionals in developing Bottle Filling Machine, glass filling machine, pouch filling machine and 20 tr jaar filling machine. The offered plants are widely used for washing, filling and capping of drinks such as mineral water, pure Water and non-gas wine drink.

We offer automatic bottling plants:

- Fully automatic fill, rinse, capping machines

- Semi automatic fill, rinse and capping machines

- Filling size: 300 Ml, 500 ML, 1.0 L, 5.0 L & 25.0 L

Demineralization Plants

Demineralized water also known as Deionized water, water that has had its mineral ions removed. Mineral ions such as cations of sodium, calcium, iron, copper, etc and anions such as chloride, sulphate, nitrate, etc are common ions present in water. Deionization produces a high purity water that is generally similar to distilled water, and this process is quick and without scale buildup.

Demineralization Water Treatment Plant is set up to treat the filtered water, convert into good quality water. The Demineralization Water Treatment Plant can operate at different temperature ranges and feed TDS. However, variations is the permeate water quality are anticipated. Demineralization Water Treatment Plant can be divided into two major sections, for easy familiarization with the various unit : Pretreatment Section and Reverse Osmosis Section.

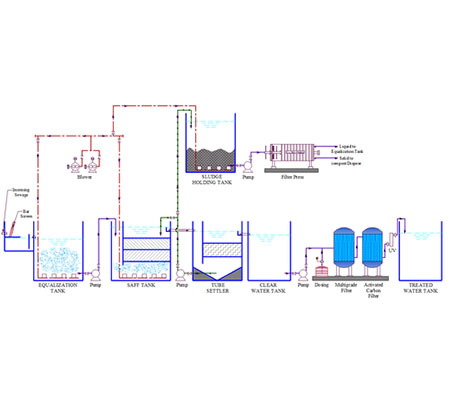

Effluent Treatment Plant

Effluent from the industry process affects the biological balance of the receiving streams, lakes, river and ground water. The main consideration of effluent treatment should be that the water quality of the stream or ground water is not adversely affected by the discharge of the effluent.An Effluent treatment plant is meant to remove the settle able solids, floating particles and to reduce the biological & chemical oxygen demand (BOD & COD).

Olympia Eco Solutions Private Limited is recognized for offering excellent effluent treatment system for water management.

The Principal objective of Olympia Eco Solutions Private Limited is to produce a treated effluent and a solid sludge suitable for discharge or reuse back into the environment. Our company has packaged sewage & effluent treatment plants to meet all expectations of customers.

We offer a wide range of industrial effluent treatment plants for application in

- Textile

- Paint

- Beverage

- Automobile industries,

- Diaries

- Paper mills

- Oil refineries

- Leather industry

- Glass factories

- Chemical and processing industries etc.

Mechanical Evaporators

Olympia Eco Solutions Private Limited offers custom built solutions covering every possible aspect of the concentration of industrial fluids with a vast process experience, expertise in Design, Engineering and Process Integration, unparalleled fabrication facilities and a state of art Pilot Plant.

Olympia Eco Solutions Private Limited offers Evaporation Plants with the most optimal operating cost in variance applications such as

- Fertilizers

- Pharmaceutical

- Food and chemical

- Herbal Extracts

- Dyestuff

- Black liquor in Paper & Pulp

- Sugar Syrups

- Ammonium Nitrate

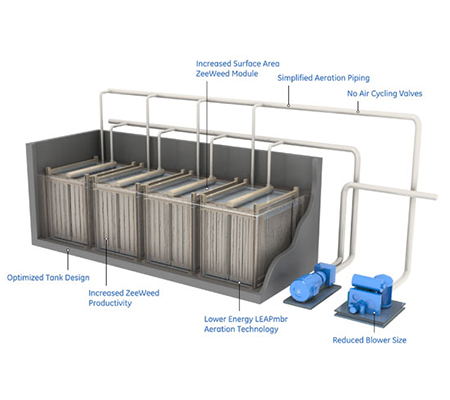

Membrane Bio Reactor

The term ‘membrane bioreactor’ (MBR) is generally used to define wastewater treatment process used in place of the secondary sedimentation tank and sand filter used for tertiary treatment in the conventional activated sludge process. Membrane Bio-reactor (MBR) is a process where a perm-selective membrane eg microfiltration or ultrafiltration is integrated with a biological process – a suspended growth bioreactor.

When used with domestic wastewater, MBR processes could produce effluent of high quality enough to be discharged to coastal, surface or brackish waterways or to be reclaimed for urban irrigation.

Olympia Eco Solutions Private Limited provides features such as space saving, easy operation and high quality treated water which is reusable. In addition, advanced treatment of nitrogen and phosphorus removal can be achieved by anoxic / aerobic treatment with respect to customer requirements and site conditions

Micro Filtration Plants

Micro Filtration is a filtration process which removes contaminants from a fluid (liquid & gas) by passes through a micro porous membrane. A typical microfiltration membrane pore size range is 0.1 to 10 micro meters (µm). Microfiltration is fundamentally different from reverse osmosis and Nano filtration because those systems use pressure as a means of forcing water to go from low pressure to high pressure. Microfiltration can use a pressurized system but it does not need to include pressure.

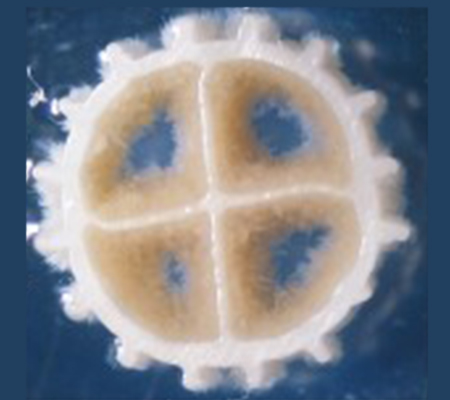

Moving Bed Bio Reactor

MBBR (Moving Bed Bio Reactor) is an Advanced Aeration system with many advantages. Maintenance of this plant is very easy and no MLSS (Mixer Liquid Suspended Solids) require maintaining for BOD / COD Neutrificant. BOD / COD removal will be done through a floating medias with high surface area by means of air flow in to the aeration tank.

MBBR (MOVING BED BIO REACTOR) tanks where it will be mixed with living organism also called MLSS (Mixed Liquor Suspended Solids) in presence of air & air shall be introduced through submerged air diffusers (MLSS in aeration tank shall be maintained 2500-3000 Mg/L). The MBBR system shall be designed in a way so as to achieve complete mixed or organisms with raw Kitchen Effluent. After achieving a complete mixing of organism over a retention period of 4 hrs, the effluent would flow via gravity in to the Tube settler. In the tube settler, PVC Tube Media would be provided to enhance setting of the sludge with attached setting process. Through the use of the baffles the liquid in the Tube Settler is maintained in quiescent condition with allows the solids to settle to the bottom for collection. Addition of Polymer based settling chemicals will feed using a metering pump for vfast settling. The accumulating solids know as “Sludge” shall be constantly pumped back in to the MBBR tank by sludge recycle pumps. This return sludge undergoes further digestion in the aeration tank and also provides the active organism needed to digest the incoming raw sewage.

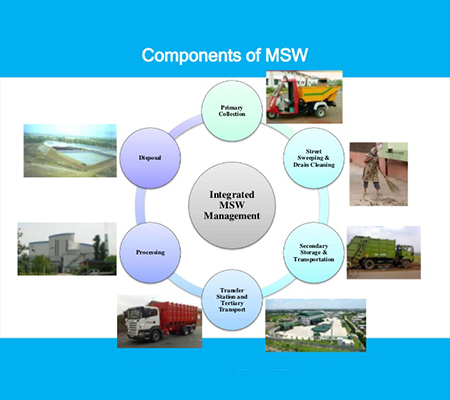

Municipal Solid Waste Management

The solid waste management methods considered in the scenarios were collection and transportation of wastes, source reduction, Material Recovery Facility (MRF)/Transfer Stations (TS), incineration, anaerobic digestion and landfilling. Our goal was to determine the most environmentally friendly option of MSWM system. The inputs and outputs of each management stage were defined and the inventory emissions calculated by the model were classified in to impact categories; non-renewable energy sources exhausting potential, final solid waste as hazardous and non-hazardous, global warming, acidification, eutrophication and human toxicity. The impacts were quantified with the weighing factors of each category to develop the environmental profiles of each scenario. In the interpretation and improvement assessment stage, the results were further evaluated and recommendations were made to improve the current Municipal Solid Waste Management system.

Nano Filtration Systems

Nano filtration is a relatively recent membrane filtration process used most often with low total dissolved solids water such as surface water and fresh groundwater, with the purpose of softening (polyvalent cation removal) and removal of disinfection by-product precursors such as natural organic matter and synthetic organic matter.Nano filtration is also becoming more widely used in food processing applications such as dairy, for simultaneous concentration and partial de mineralisation.

Reverse Osmosis Systems

Reverse osmosis is a membrane separation process for removing solvent from a solution. When a semi permeable membrane separates a dilute solution from a concentrated solution, solvent crosses from the dilute to the concentrated side of the membrane in an attempt to equalize concentrations. The flow of solvent can be prevented by applying an opposing hydrostatic pressure to the concentrated solution. The magnitude of the pressure required to completely impede the flow of solvent is defined as the “osmotic pressure”. If the applied hydrostatic pressure exceeds the osmotic pressure (see figure below), flow of solvent will be reversed, that is, solvent will flow from the concentrated to the dilute solution. This phenomenon is referred to as Reverse Osmosis.We offer wide range of state of the art Reverse osmosis plants for domestic, Commercial & industries to treat water, waste water, waste water recycling etc.

Sea Water Desalination Plants

Desalination process refers to any of several processes that remove some amount of salt and other minerals from saline water to produce fresh water suitable for human consumption or irrigation. One potential byproduct of desalination process is salt.Desalination process is used on many sea going ships and submarines. Most of the modern interest in desalination is focused on developing cost-effective ways of providing fresh water for human use.

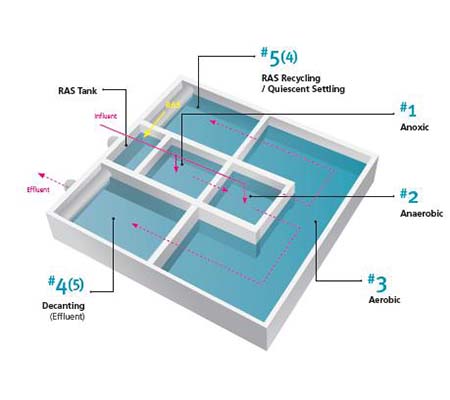

Sequencing Batch Reactors

The Sequencing Batch Reactor (SBR) is an activated sludge process designed to operate under non-steady state conditions. An SBR operates in a true batch mode with aeration and sludge settlement both occurring in the same tank or more.The major differences between SBR and conventional continuous-flow, activated sludge system is that the SBR tank carries out the functions of equalization aeration and sedimentation in a time sequence rather than in the conventional space sequence of continuous-flow systems.In addition, the SBR system can be designed with the ability to treat a wide range of influent volumes whereas the continuous system is based upon a fixed influent flowrate. Thus, there is a degree of flexibility associated with working in a time rather than in a space sequence.

Sewage Treatment Plants

With extensive years of experience, Olympia Eco Solutions Private Limited is committed to deliver creative solutions to meet your most stringent water quality requirements. Olympia Eco Solutions Private Limited understands that effective primary wastewater treatment is critical to your plant operations, whether you are treating prior to your own biological wastewater treatment system or discharging directly to a municipal wastewater treatment system.

Olympia Eco Solutions Private Limited has an excellent track record in Turnkey supply of Sewage treatment plants. Sewage is created by residential, industrial, institutional and commercial establishments. We have expertise in providing superior designs, planning, execution & commissioning of plants of various capacities and wide design range. The treated water can be discharged into water receiving systems and the solid waste can be used as manure.

Submerged Aerobic Fixed Film Reactors

- This is a package type plant requiring very less civil works as compared to conventional plant.

- The plant does not require dedicated / skilled manpower.

- This is because the aeration tank has been provided with non corrosive, fluidized media which acts as site for micro-organism growth. Return of sludge to maintain MLSS in aeration tank is not required thus avoiding need for dedicated operators.

- The cost of civil works is very less and the plot area for construction is also saved.

- Low power Consumption.

- Low manpower Cost.

- Ease of operation and maintenance due to special features of SAFF reactors.

- Standby units provided for all rotating equipments.

- Frequent handling of sludge in avoided.

Ultra Filtration Systems

Ultra filtration (UF) is a variety of membrane filtration in which hydrostatic pressure forces a liquid against a semi permeable membrane. Suspended solids and solutes of high molecular weight are retained, while water and low molecular weight solutes pass through the membrane. This separation process is used in industry and research for purifying and concentrating macro-molecular solutions, especially protein solutions. Ultra filtration is not fundamentally different from micro-filtration, Nano filtration or gas separation, except in terms of the size of the molecules it retains. Ultra filtration is applied in cross-flow or dead-end mode and separation in ultra filtration undergoes concentration polarization.

Water Treatment Chemicals

Olympia Eco Solutions Private Limited supplies chemicals for the Water treatment process. Water treatment process is classified into various types. Each treatment process needs different method and chemicals for the purification of water. Olympia Eco Solutions Pvt. Ltd., supplies various chemicals suitable to the various treatment methods.